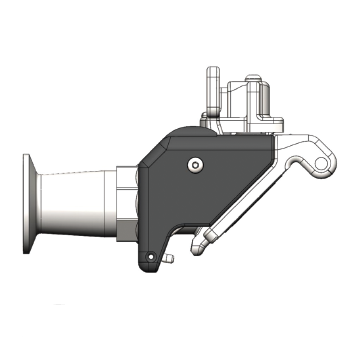

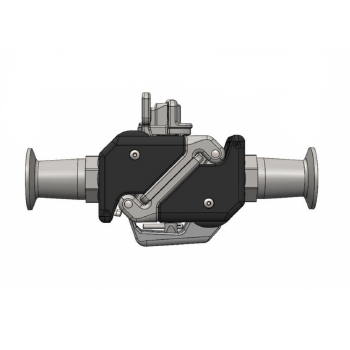

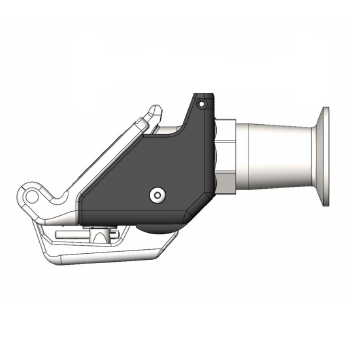

Dry-disconnect (dry-break) couplings are preferred where no spills, drips, or user exposure can be tolerated, and are especially useful when transferring hazardous, toxic, or corrosive chemicals. The couplings are ergonomic, easy to use, and allow for a higher Cv value when compared to alternative solutions. Dry Link can also be ideal for eliminating cross-contamination.

Many Sizes & Options Available

Standard sizes include 1/2″, 3/4″, and 1″ Tri-Clamp, with up to 3″ Tri-Clamp and various NPT or CAM Lock connections also available. Dry Link Couplings are sold standard with 316 stainless steel wetted components, but are also available in Hastelloy and other engineering metals. Many material options are also available for the seals including PTFE and FKM (contact us for details).

Features and Benefits

- Maximize safety and ergonomics

- Serial number on each disconnect for traceability

- Wetted surfaces electropolished (20Ra or better)

- USP Class VI o-rings and seals

- Temperature Range: 20°F to 230°F

- Maximum Pressure: 210 PSI

- Cross contamination control

Example Applications

- Pharma and Biopharma

- Chemical manufacturing

- Cosmetics

- Adhesives

- Inks

- Pulp & Paper

- Hazardous waste conveyance

- Rubber & plastics manufacturing

Dry Disconnect (Dry Break) Coupling Demonstration

Learn more about how our dry disconnect couplings work and what we offer.

Pharmaceutical Manufacturers Respond To Potential Supply Interruptions

Partnering with Fluidline Technologies

For Immediate Release Acuity Process Solutions in North Attleboro Massachusetts is pleased to announce that…

Acuity Process Solutions can help you find drawings and replacement parts for Precision Stainless Tanks and Pressure Vessels

The demand for used sanitary process equipment has been on the rise. Stainless tanks and…