The demand for used sanitary process equipment has been on the rise. Stainless tanks and pressure vessels are generally on the top of the list due to the high cost for new tank fabrications.

For years Precision Stainless was a leader in stainless tank and pressure vessel fabrications. Based on their reputation for quality, Precision Tanks are widely sought after on the used equipment market.

Buying a used tank or pressure vessel can be a huge savings, however, they will generally need modifications or replacement parts to fit your application.

As the New England Represent for HOLLOWAY AMERICA, Acuity Process Solutions is pleased to inform you that both Drawings and replacement parts are available.

HOLLOWAY AMERICA has continued the Precision Stainless product line since 2007, and maintains an extensive database of CAD drawings and replacement component information for the large majority of Precision Stainless tanks and pressure vessels.

The Acuity Process Solutions Team can help you locate drawings or replacement parts in a few simple steps.

- Traceability – The Vessel data Plate.

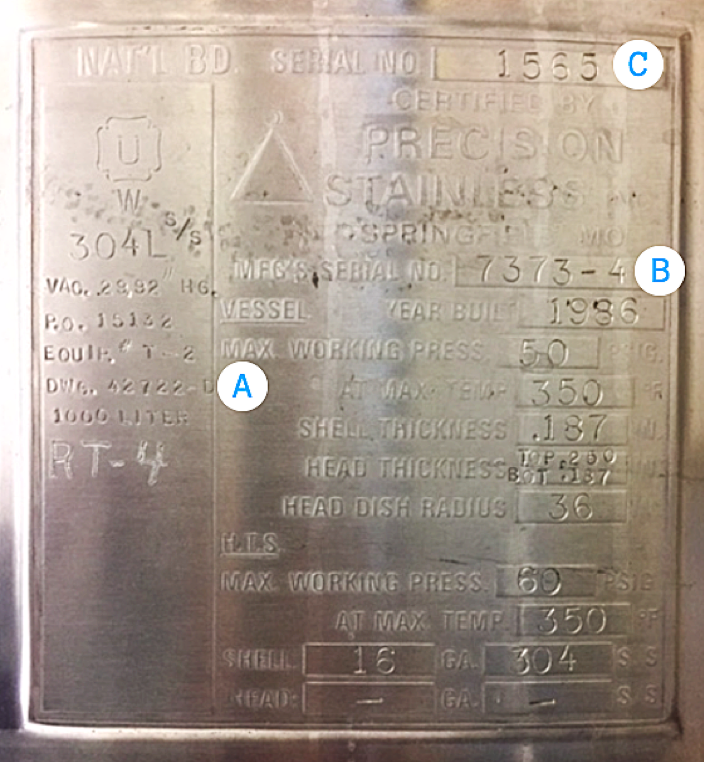

The vessel data plate contains all of the information necessary to retrieve the original specifications and drawings for each tank.

- Locate the drawing number on the data plate.

A five digit number on the data plate followed by a “D” or “-D”. This is referred to as the drawing number. Holloway will use this number to search against their extensive database of pressure vessels.

The image above is an example of a Precision Stainless tank data plate. In This is an example of the standard format of the Precision Stainless data plates, from 1984 to around 1990,. In later years, the format changed moving the notes section to the bottom of the data plate.

The following information is the most relevant when searching the database.

- The vessel drawing number, (shown above as DWG; 42722-D) is the most important piece of information allowing us to quickly cross reference the documentation.

- The vessel serial number, (shown above as 7373-4), indicates the work order for the project. The “-4” indicates the 4thvessel on that order. Looking up the vessel information through the serial number can be done, but it is not as effective as the vessel drawing number.

- The National Board Serial Number, (shown above as 1565), is a sequential number assigned to every code vessel that is fabricated by a manufacturer. Cross reference by this number is a much slower process than by the vessel drawing number or serial number.

- Email the drawing number to us.

An Acuity Process Solutions service professional can help you with this process. Simply email the information requested above to CustomerService@AcuityProcess.com or call us at 508-809-5099 to schedule a field visit for further support.

Whether you’re working to validate a functioning Precision Stainless vessel and require drawings or replacement components, let Acuity Process Solutions help bring your pressure vessel back to life!

Leave a Reply

You must be logged in to post a comment.