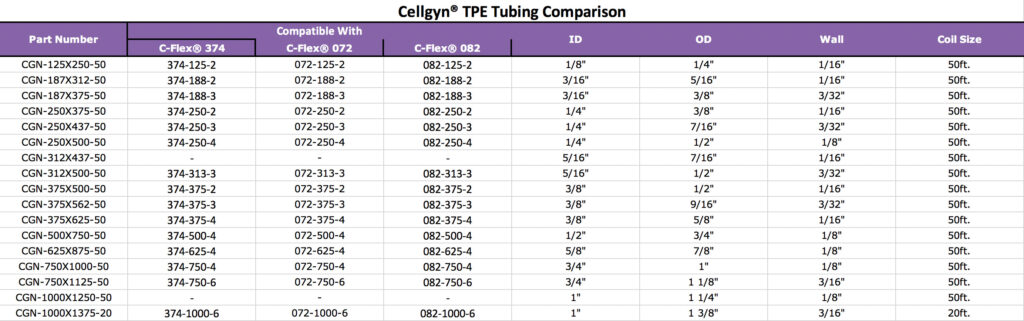

Acuity is proud to represent TBL Plastics based in Sparta NJ. TBL produces their proprietary Cellgyn ADIF TPE Material in 17 different sizes/wall thicknesses, a significant portion of which is readily available and in stock. It is available as bulk tubing or can be fabricated into tube-sets based on customer requirement. TBL maintains an in-house ISO 7 cleanroom assembly area and can provide cleanroom packaging solution as well as gamma irradiation management.

Tubing made from either Thermoplastic Elastomer (TPE) or silicone are commonly used in critical Life Sciences manufacturing processes throughout the world. How does one choose which material to use? To understand one major consideration, it’s helpful to understand the differences in the materials.

Silicone is a thermoset material, meaning that it is extruded and heated to form the final shape that it will hold. As it cools, the material undergoes a chemical linking and permanently changes its physical structure. It cannot be reheated or re-molded. In order to join tubing together, mechanical joining methods such as a hose barb must be used.

TPE, on the other hand, is a thermoplastic material meaning that it can be heated and molded multiple times. Because of this, the material can be heat welded and/or sealed. This enables tubing to be joined together without the use of mechanical fasteners, minimizing potential for leak paths or contamination.

In addition to considering the joining method, one must consider temperature and pressure capability, leachable/extractable concerns, permeability, as well as chemical compatibility.

In-house studies have demonstrated that Cellgyn can be successfully welded to TPE formulations from other major manufacturers such as C-Flex™. TBL has completed an exhaustive survey to test the weldability of Cellgyn to C-Flex™ grades 082, 072, and 374, both pre-gamma irradiation and post-gamma irradiation and has demonstrated successful welds with no loss of integrity.