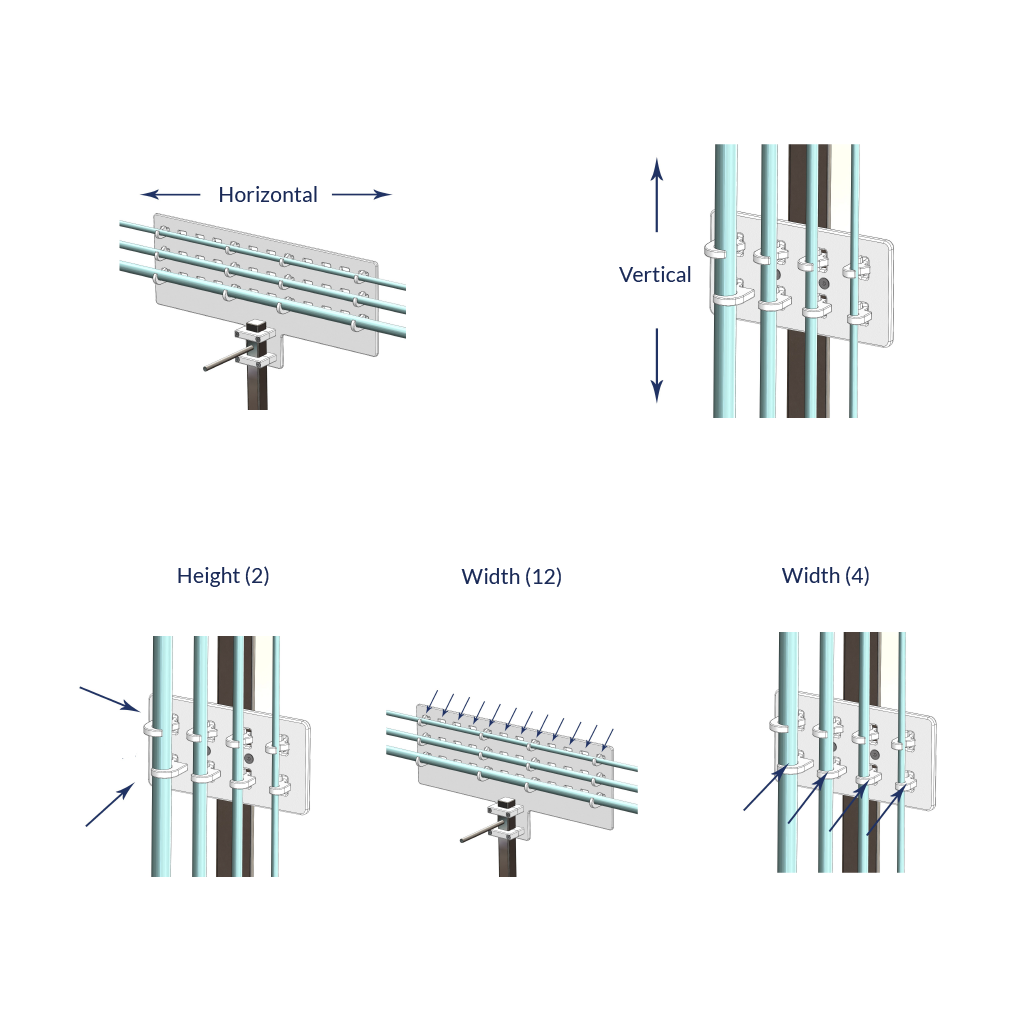

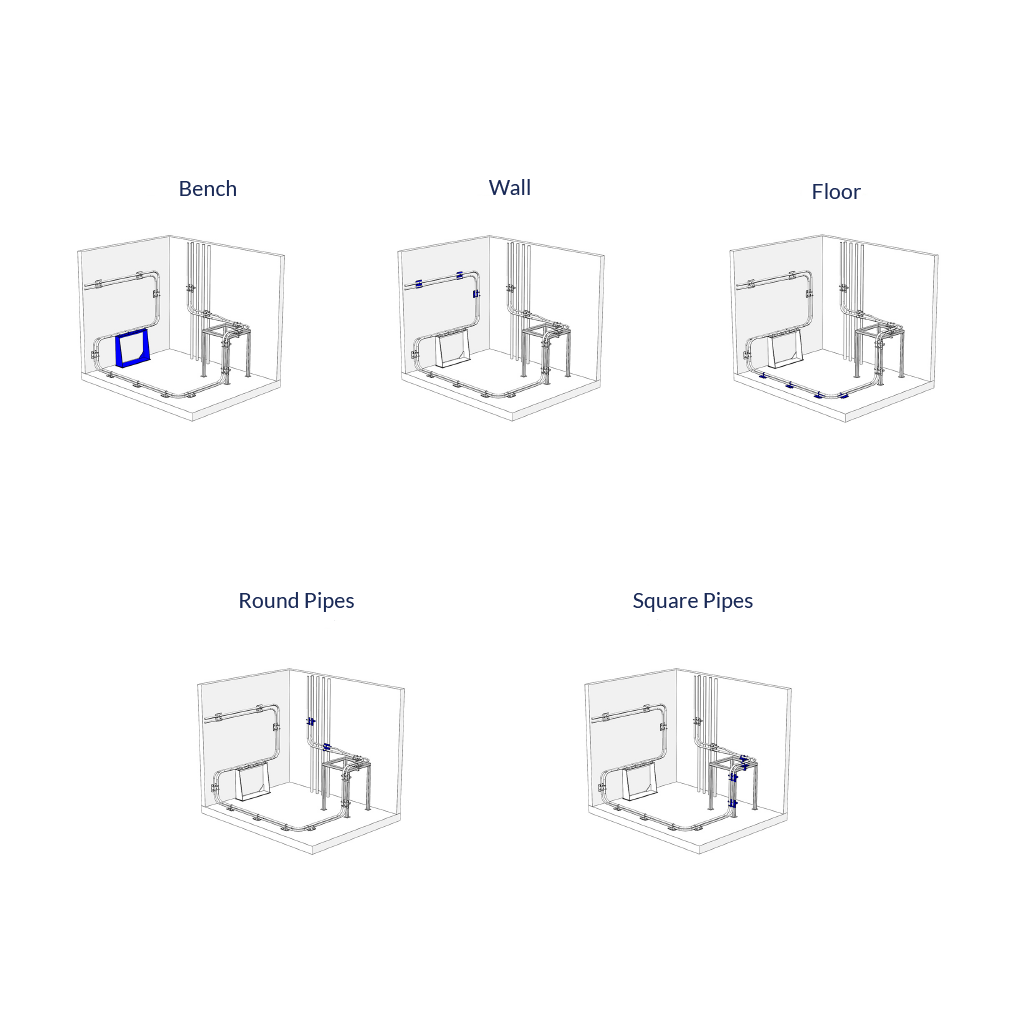

T-LOC is a proprietary tubing management system designed to organize and protect critical fluid paths for bioprocessing and other critical process applications utilizing flexible tubing. The T-Loc system combines a mounting bracket with a flexible-tubing hanger system that enables operators to install and remove single-use tubing assemblies in a repeatable and validatable way.