Single-Use Filling Needles & Assemblies

Featured Supplier: SaniSure

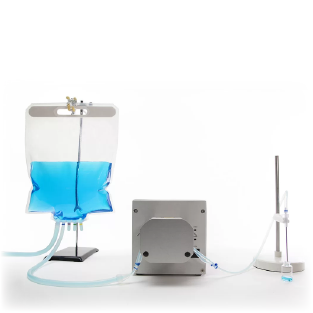

Fill4Sure filling needles and assemblies from SaniSure are the optimal choice for bioprocess-filling applications. Made exclusively in the USA through a proprietary adhesive-free and oil-free process, Fill4Sure needles are maintained to the highest purity and precision standards. The standard materials of construction include ISO 9626 stainless steel needle tubing, USP Class VI polycarbonate, USP Class VI PEEK, or other customer specified materials, and the needles are offered in metallic, non-metallic, or as a metal-non-metal composite. With many pre-engineered and custom options to fit a variety of OEM filling equipment, we have solutions for most filling systems in the industry. In addition, SaniSure’s exclusive needle-protection block and strap system is one of the best solutions available for protecting the integrity of your needles and bags. Whether you need a filling needle or complete turnkey filling assembly, Acuity can help.

Some filling-needle manufacturers make their needles with oils and adhesives, which can cause unpredictable spikes in terms of exctractables and particles generated. Fill4Sure needles are made exclusively in the USA without the use of adhesives or oils. Why add risk to your process by introducing possible adhesive or oil contamination at your fill point?

Fill4Sure needles are available as pre-engineered or custom with comprehensive options to fit the majority of bioprocess filling equipment in the industry. In fact, with custom needle hubs to fit most needle holders, Fill4Sure systems are commonly used to replace OEM assemblies and needles.

Fill4Sure needles are available as pre-engineered or custom with comprehensive options to fit the majority of bioprocess filling equipment in the industry. In fact, with custom needle hubs to fit most needle holders, Fill4Sure systems are commonly used to replace OEM assemblies and needles.

Whether you need a fully non-metallic needle, a fully stainless needle, or a combination of both, Acuity has you covered. Featuring ISO 9626 stainless steel needle tubing, USP Class VI needle hubs, and an adhesive/ oil free design, there are many possibilities for customization. Coaxial needles are also available for applications where gas and liquid filling are required.

Without the proper capability to protect your needles and bags up to the point of use, you may run into challenges in terms of protecting the integrity of the needles (e.g. damage to the tip, straightness issues, or breakage) or puncturing the bag. SaniSure has developed perhaps the most robust solution in the industry to deal with this common gap found in bioprocess filling applications.

- Drug Product Filling

- Cell and Gene Therapy

- Drug Substance Aliquoting

- Co-axial Liquid/Gas Filling

- Biotech Reagants

- Media Filling

- USP Class VI Polymers

- ISO 9626 Compliant SS Needle Tubing

- Non-Metallic, Metallic, or Composite Designs

- Proprietary Needle Protection Block/Strap System

- ISO 11137 sterility program

- Coaxial Liquid/Gas Filling Capabilities

Contact Acuity today for a quote on Fill4Sure single-use filling needles and assemblies. We are here to help every step of the way from the concept stage all the way to full commercial manufacturing and commonly work with our customers to provide extensive drawings, quality packages and other technical resources for specifying components and systems in to their process.

Acuity Process Solutions to Showcase Future-Ready Systems to Simplify Your Bioprocess: ISPE Boston 2025

Live Demo at the ISPE CaSA Tech Show: February 25th, 2025!

Revolutionizing Water-System Design: The Case for Early Adoption of EilerCal & PUREX