While certified test weights remain the “gold standard” for highly-accurate load-cell calibrations, they become impractical when attempting to calibrate larger vessels at full scale. Weights are heavy, dangerous, and expose employees to ergonomic and safety issues. While viable on smaller pieces of equipment, weights become unwieldy as vessel capacities increase.

When weights become impractical, historically the best option was to use a calibrated flowmeter. By regulating the amount of water that is added to a tank, one can determine the weight that has been added to the tank; For example, 1 Liter of water at standard pressure and 4 degrees Celsius weighs 1KG*. However, using a flowmeter has some challenges as well:

- In practice, there are a number of variables that can affect the accuracy of a calibration utilizing a flowmeter.

- Water calibrations take a significant amount of time. Adding thousands of liters of water to a tank can take hours depending on the water system and pump capacities. On top of that, the tank must be drained and in many cases cleaned post-calibration, which can be more time consuming than filling.

- Water can be expensive. When calibrating large tanks in pharmaceutical and bioprocessing applications, WFI (Water for Injection) is typically utilized. There are substantial costs incurred to generate WFI that must be considered; recent surveys of industry-leading clients range from $2.00USD per liter to more than $7.00USD per liter.

- Pharmaceutical and Biopharmaceutical tanks or vessels likely require sanitization/sterilization after calibration.

- Calibrating single-use tanks, carts, mixers, and bioreactors introduces another set of concerns. Because the rigid container that surrounds the single-use bag cannot hold water by itself, a sacrificial bag must be installed, adding additional cost above the cost of the water. Some clients employ new bags which are expensive, and others employ used bags which can be difficult to store after their first use, may have contaminants that are odiferous, or may be more likely to rupture during calibration.

Introducing EilerCal: The Ultimate Solution for Load-Cell Calibration

Enter EilerCal, a new force-calibration technology form Eilersen Calibration Solutions, offering a cost and time saving alternative to the traditional flowmeter calibration.

Enter EilerCal, a new force-calibration technology form Eilersen Calibration Solutions, offering a cost and time saving alternative to the traditional flowmeter calibration.

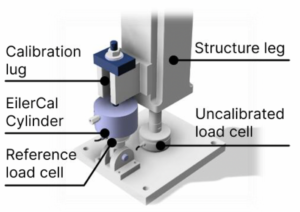

The EilerCal System is directly connected to a tank or vessel and employs one or more hydraulic cylinders to apply downward force which is measured by its on-board reference load cell. The reference load-cell measurement is then used as the standard against which the vessel’s load cells are calibrated. The system may consist of a single or multiple cylinders selected to match the tank design and installation.

- EilerCal is non-intrusive to the tank. Force is applied to the outside of the vessel via different attachment points, enabling a user to design an installation that is easily accessible.

- EilerCal is portable. One EilerCal System (which may consist of a single or multiple cylinders) can be used to calibrate a number of tanks.**

- EilerCal is lightweight. One calibration cylinder weighs less than 20lbs.

- Based on the Eilersen digital capacitive load cell technology, EilerCal is extremely robust and can withstand normal handling without losing calibration.

- EilerCal is fast. Attaching the cylinders takes only minutes and applying full hydraulic load can be accomplished with just a few strokes of the hydraulic pump. A tank that may have taken hours (or days!) to set up and calibrate with water can be calibrated with EilerCal in 30 minutes or less.

- EilerCal is adaptable. Custom systems can be designed to speed calibration of fleets of mobile mixers/tanks.

- EilerCal uses no water, no single-use bags, and no hose connections making it an attractive choice for calibrating load cells in pharmaceutical and biopharmaceutical applications. It saves significant cost per calibration as compared to other methods.

For End-Users:

EilerCal can reduce calibration cost, and more importantly speed your equipment turnaround time helping to maximize production. Time is money, and EilerCal is proven to save significant time.

For OEM Equipment and Tank Builders:

System Builders are constantly working to differentiate their product offering against the competition. Consider offering the EilerCal system as an add-on to your equipment by integrating the EilerCal attachment points into your systems. You’ll be ahead of the pack when it comes to the new sustainable way to calibrate.

*There can be a slight variation based on isotopic ratios of oxygen and hydrogen, but for the purpose of this article we consider 1L to be equal to 1KG

** For maximum accuracy, the EilerCal system should be properly sized to match vessel loading.

Leave a Reply

You must be logged in to post a comment.