What are Dry Disconnect Couplings?

Dry Disconnect Couplings are designed for quick and spill free connection and disconnection of hoses and pipelines. They are used by producers of ink, adhesives, fatty acids, pharmaceuticals, liquid soaps, petroleum, chemicals, agricultural and a wide variety of caustic products and specialty acids. Dry Disconnect Couplings, also called dry break couplings and dry break couplers, can be found in various applications such as handling toxic chemicals, fuels etc. to transferring clean water. Due to the wide range of materials, connections and sealing types, Dry Disconnect Couplings are flexible enough to suit almost any application.

Benefits of using Dry Disconnect Couplings

- Reduces spillages to virtually zero

- Helps minimize effects on the environment

- Increased safety (operator exposure)

- Minimizes expensive product loss

- Dramatically improves both operational and fugitive emission performance

- Reduces the possibility of human error in transfer operations

- Improves efficiency

- An unbeatable combination of technical, safety and performance features

There are a lot of styles on the market and choosing the correct one can depend on the following factors…

How to Choose the Correct Dry Coupling

Flow Restriction – Some types are inline push-to-connect styles that have integral check valves. They can impart a large restriction to flow.

Ease of Operation – Depending on the size of the connection, the disconnect can be difficult to operate (large push-to-connect fittings require a lot of force).

Weight – Larger units can weigh a lot.

No drips, No Spills

Dry Disconnect Couplings should trap fluids before they drip onto the floor or ground. Even small drips can pollute or be dangerous or expensive. Make sure the dry disconnect coupling you go with is 100% drip-free.

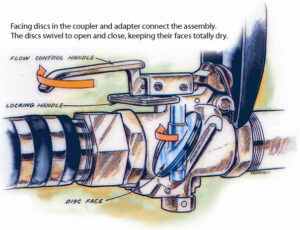

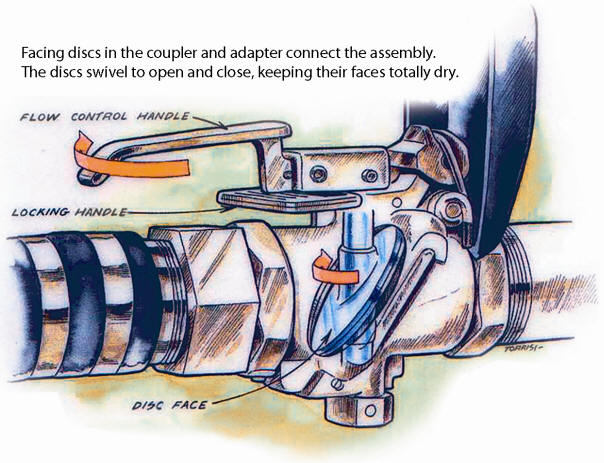

The flow shut-off mechanism resembles a butterfly valve with very low flow restriction. This design enhances flow while also reducing the risk of internal gunk-ups that can lead to connection malfunctions. A safety interlock prevents accidental opening, and a unique sealing arrangement results in the world’s most drip-free dry disconnect.

Save Time When Finding The Right Dry Disconnect Coupling

In order to save time during your process, when searching for dry disconnect couplings you want to make sure the one you have has a built-in swivel end in coupler for easy hose alignment. Dry Link, the premier manufacturer of dry-disconnect carries dry disconnects with this feature, and also are up to 50% lighter than comparable dry disconnect couplings. They also are easy to maintain, and have accessible parts.

Dry-disconnect couplings should be able to be used anywhere a hose is used to transfer fluids, especially where the fluids are hazardous, toxic, corrosive or flammable. This includes bulk fluid transfer applications such as tank trucks, railroad cars, and portable tank containers. It also includes in-plant switching manifolds and moving equipment such as portable batch reactor vessels.

Depending on your applications, make sure the dry disconnect couplings you are considering have been tested and your provider can show you a comprehensive documentation package to meet your validation requirements.

The following is a list of certifications to ensure your dry disconnect coupling meets your application’s requirements. Dry Link supplies all of these upon request.

- Material test certification (heat lot codes with chemical and physical properties)

- Seal material certification (FDA and USP certifications)

- Certificates of conformance

- Production test certificates (pressure test certificates)

- Certified drawings

Dry Disconnect Couplings Can Be Customized

Dry Link disconnects are available in various material of construction, sizes, end connections and surface finishes. In addition, Dry Link valves are completely customizable. For example; Eccentric and Concentric reducers can be welded as an integral part of the adaptor or coupler for drain ability. (or to reduce pressure drop) Our design engineers will help you specify the right valve for your application.

Avoid Fines with Dry Disconnect Couplings

If chemicals drip, you may find yourself in the midst of thousands of dollars in fines. Drylink’s dry disconnect couplings use a unique patented drip-free design to trap chemicals before they leak on the ground or floor. This will allow you to avoid expensive spills while protecting both workers and the environment. Plus, Dry Link’s couplings are compact and lightweight for easy handling and use fewer internal components for maximum flow.

Acuity Process Solutions represents Dry Link, Inc. Drylink is the premier manufacturer of dry-disconnect “dry break” hose couplings for bulk transfer of liquids, & high-containment split-butterfly valves for powders.

Their industrial couplings are specified worldwide in chemical & petrochemical industries to provide drip-free connections. When hygienic conditions are required, Drylink’s sanitary high-purity line of couplings are specified by all major pharmaceutical, biotechnology & food companies.

Protect both the environment and your employees while also avoiding costly clean-ups. Conserve every drop of precious commodities by using Dry Link’s Dry Disconnect Couplings.

If you are looking for Dry Disconnect Couplings and need a hand, you can contact us HERE. For more information about Dry Link, please visit the Dry Link product page.

Leave a Reply

You must be logged in to post a comment.